Quality Management System

Precision and Performance Backed by Comprehensive Inspection

Quality Control Equipment

CNC Coordinate Measuring MachineCRYSTA APEX776[MITUTOYO]

- Year Introduced

- 2020

- Specialty

-

Detects three-dimensional coordinates (X, Y, Z) to accurately capture the position and geometry of workpieces.

- ・E=(1.9+4L/1000)㎛

CNC Coordinate Measuring Machine Bright Apex707[MITUTOYO]

- Year Introduced

- 1998

- Specialty

-

In 2021, with support from Renishaw, it was upgraded to achieve repeatability surpassing its original specifications, even after over 20 years in operation.

- ・E=(2.9+4L/1000)㎛

3D Scanner-Type Coordinate Measuring MachineVL-500[KEYENCE]

- Year Introduced

- 2021

- Specialty

- Performs 360° 3D scanning of any shape, comparing results with original 3D CAD data for shape comparison and difference analysis.

Tool PresetterISⅢ-6040[KYORITSU SEIKI]

- Year Introduced

- 2016

- Specialty

- Non-contact measurement using a CCD camera.

Other Measuring Instruments

| Instrument Name | Model | Manufacturer | Specifications | Units |

|---|---|---|---|---|

| Coordinate Measuring Machine | Crysta-Plus M55 | MITUTOYO | X500 Y400 Z400 | 1 |

| Coordinate Measuring Machine | A-121 | MITUTOYO | X500 Y400 Z300 | 1 |

| Precision Profile Projector | PJ-300 | MITUTOYO | 1 | |

| Length Measuring Instrument | SM-3 | KURODA SEIKO | L300 | 1 |

| Length Measuring Instrument | TELMA500 | TRIMOS | L500 | 1 |

| Surface Roughness & Contour Tester | SURFCOM | TOKYO SEIMITSU | 1 | |

| Roundness Measuring Instrument | EC500 | KOSAKA | Max φ420 (ID/OD) | 1 |

| Air Micrometer | DAIICHI SOKUHAN | φ4〜φ60 | 30 sets | |

| Ceramic Gauge Blocks | MITUTOYO | 3 sets of 103 pcs | ||

| Pin Gauges | φ2〜φ20 (in 0.01 mm increments) | 2,000 pcs | ||

| Block Holders | KURODA SEIKO | φ14〜φ150 | 2 sets | |

| Ring Gauges | φ1.75〜φ180 (for internal measurement) | 250 pcs | ||

| Rockwell Hardness Tester | NAKAI SEIKI | 1 |

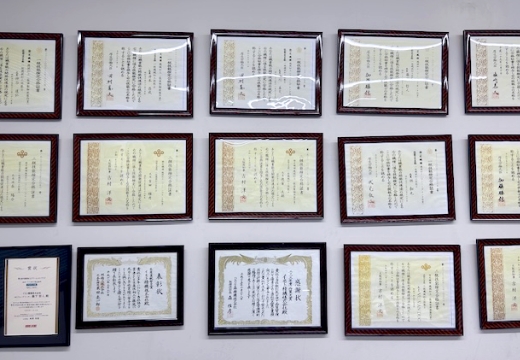

Human Resource Development

Our in-factory information terminals are connected through the company network, allowing all employees to share technical and quality-related information. Easy access to this data streamlines operations, while a database of standardized procedures supports continuous skill improvement across the entire team.

A commitment to uncompromising quality fosters a strong sense of professionalism in every staff member. We also encourage employees to take national skill certification exams relevant to their work. These certifications assess the proficiency of skills required on the job, and those who pass are officially recognized as “Certified Skilled Workers.”